Directional Boring Techniques: A Complete Reference for Contractors

Directional boring methods constitute a critical advancement in underground construction. These techniques enable streamlined utility installations with reduced surface disruption. Contractors should navigate numerous challenges, including equipment selection and soil conditions. Acknowledging the importance of safety and real-time monitoring can greatly impact project outcomes. Comprehending these factors is essential for successful implementations. However, the intricacies of the process and emerging technologies raise further questions that necessitate exploration.

Comprehending Directional Boring: The Basics

Horizontal directional drilling, a crucial method in contemporary construction and utility installation, enables contractors to establish underground pathways with reduced surface disruption. This method involves drilling a hole underground using professional equipment, which is guided along a pre-planned path. As opposed to traditional trenching approaches, directional boring minimizes the impact on the surrounding environment, making it ideal for urban areas and sensitive landscapes.

The procedure starts with a pilot hole, which is drilled using a rotating drill bit. Once the pilot hole is formed, a reamer is connected to increase the bore to the appropriate diameter for the utility installation. This process is notably beneficial for installing pipes, cables, and conduits beneath roads, rivers, and other obstructions. Knowing the principles of directional boring equips contractors with the knowledge to properly plan and execute projects while complying with safety regulations and environmental considerations.

Critical Gear for Directional Boring

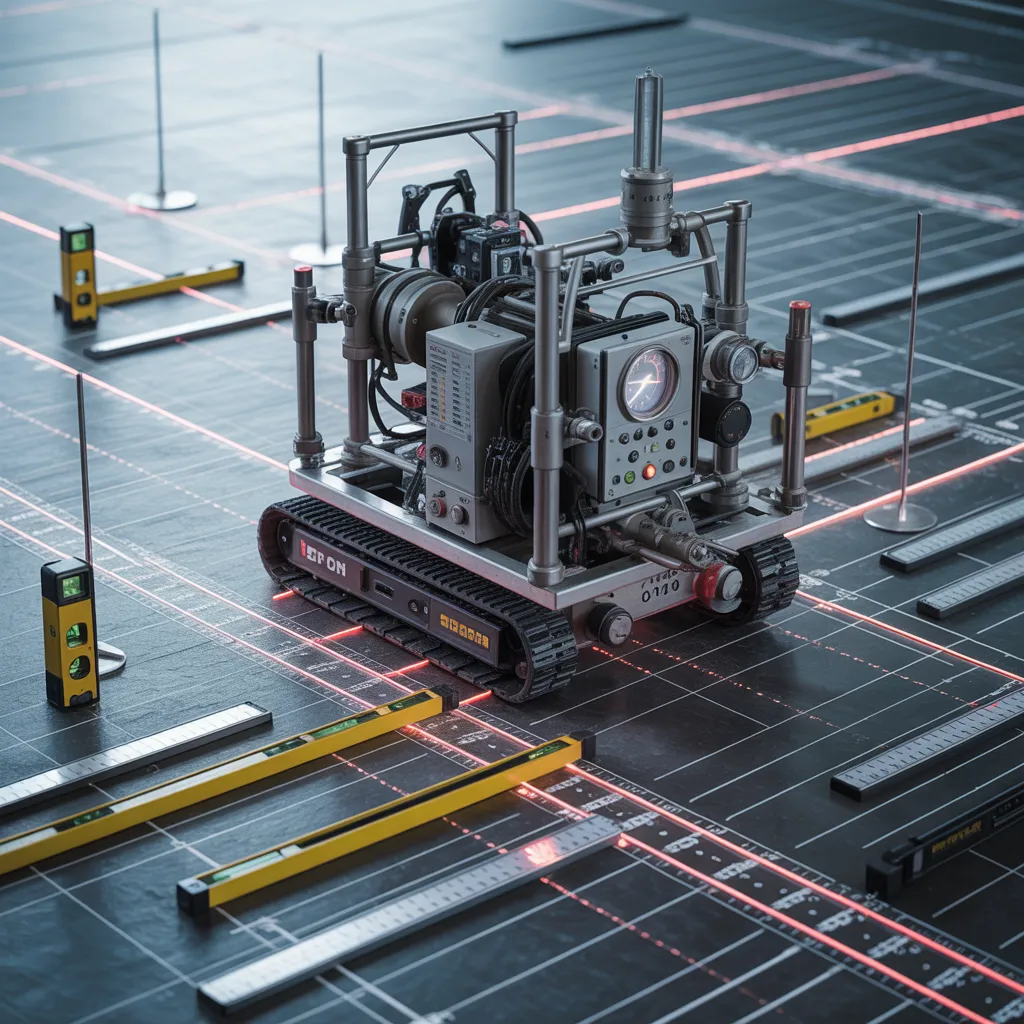

Successful directional boring requires a selection of specialized equipment designed to ensure precision and efficiency during the drilling process. Central to this operation is the directional drilling machine, which allows operators to drill at varying angles and depths while maintaining accuracy. Additionally, drill bits customized for specific soil conditions are crucial, as they impact the cutting efficiency and overall performance.

Another important component is the tracking system, which supplies real-time data on the drill's position and trajectory, confirming that the bore path remains precise. Mud pumps and drilling fluid systems are similarly crucial, as they support cooling and lubrication while clearing cuttings from the borehole. Furthermore, ancillary tools such as reamers and swivels enhance the capabilities of the primary equipment, allowing contractors to tackle diverse underground conditions. Combined, this equipment forms the basis of efficient and productive directional boring operations.

Key Techniques for Expert Directional Boring

Effective directional boring relies on proper equipment selection and a thorough assessment of soil conditions. Contractors need to pick the right tools customized for specific project requirements to maintain efficiency and safety. Additionally, understanding the soil type and its characteristics can greatly influence the boring process and overall project outcomes.

Strategic Equipment Selection

Choosing the right equipment for directional boring is vital for contractors seeking to boost productivity and performance on the job site. A thorough assessment of the project's scope and specific requirements directs the selection process. Key factors include the size and type of the drilling machine, which should align with the diameter and depth of the borehole. Moreover, contractors must evaluate the necessary drill bits and accessories, guaranteeing compatibility with the chosen equipment. It is also important to take into account the power source and mobility of the machinery, as these factors affect operational efficiency. Lastly, investing in advanced technology, such as locating systems, can increase precision and reduce costly mistakes, ultimately leading to successful project completion.

Soil Condition Assessment

Soil condition evaluation represents a crucial stage in the directional boring process, as it directly influences the choice of techniques and equipment used. Contractors must assess the soil's composition, moisture content, and density to determine the feasibility of the project. Techniques such as visual inspection, soil sampling, and geotechnical testing are used to gather essential information. Understanding soil types—whether clay, sand, silt, or gravel—helps predict how the ground will perform during boring. Additionally, identifying potential obstacles like rocks or groundwater can prevent costly delays. Accurate assessments facilitate informed decisions, ensuring that the right boring methods and machinery are utilized, ultimately increasing efficiency and reducing the risk of project failure. Proper soil evaluation is, thus, paramount for successful directional boring operations.

Safety Aspects in Directional Boring

Even though directional boring provides streamlined solutions for underground installations, it also presents distinct safety challenges that contractors must address. As a primary concern, operators should conduct detailed site assessments to identify potential hazards, such as underground utilities and unstable soil conditions. Proper training and following safety protocols are critical to reduce risks related to equipment operation and personnel safety.

Personal protective equipment (PPE) is necessary on location, which includes hard hats, gloves, and eye protection. Additionally, upholding clear communication among team members confirms that each team member knows about their surroundings and potential hazards. Contractors should also implement a detailed emergency response plan, prepared to handle any incidents that may arise.

Consistent equipment maintenance and inspections boost operational safety, lowering the possibility of mechanical failures during boring operations. By emphasizing these safety protocols, contractors can secure their workforce and secure successful project completion.

Frequent Applications of Directional Boring

Directional boring is commonly used across different industries for its capacity to install utilities and infrastructure underground with limited surface disruption. One common application is in the installation of water and sewer lines, where typical trenching methods can be both expensive and disruptive. Directional boring enables precise placement of these lines, lessening the impact on nearby landscapes.

Telecommunications companies frequently employ directional boring to place fiber optic cables, ensuring fast and efficient internet service without extensive excavation. In addition, electric utility providers use this technique for the installation of conduits for power lines, boosting reliability and safety.

HDD technology also serves environmental applications well, such as placing monitoring wells or remediation equipment, as it decreases ground disruption and conserves natural habitats. In summary, the adaptability and effectiveness of directional drilling render it a vital technique for diverse utility placements and construction undertakings.

Addressing Typical Problems in Directional Boring

Various obstacles in directional boring must be handled by contractors to achieve successful completion. Standard difficulties consist of malfunctioning equipment, problematic soil conditions, and pipeline alignment concerns. Grasping these difficulties and their fixes is critical for upholding efficiency and decreasing downtime.

Equipment Malfunctions and Solutions

Machinery breakdowns can interrupt the productivity of any directional boring project, bringing about delays and rising costs. Common issues include hydraulic failures, drill bit wear, and misalignment. Hydraulic failures typically arise from leaks or pressure drops, which can be fixed by examining connections and replacing damaged components. Drill bit wear demands regular inspections; replacing worn bits quickly maintains optimal performance. Misalignment can result from incorrect setup or navigation errors, and can be resolved by recalibrating the equipment and ensuring proper operator training. Adopting a routine maintenance schedule is critical for preventing malfunctions. In addition, keeping spare parts on hand can limit downtime, allowing contractors to respond swiftly to sudden equipment issues and maintain project timelines productively.

Soil Difficulties and Techniques

Soil properties play an essential role in the success of any directional boring project, presenting a variety of challenges that contractors must navigate. Variable soil types, such as clay, sand, or rocky formations, can alter drilling efficiency and tool wear. Additionally, high water tables may result in unstable conditions, adding complexity to the bore path. To handle these challenges, contractors can carry out thorough site surveys and soil analyses before beginning work. Implementing appropriate drilling fluids can also help maintain borehole stability and minimize friction. Installing real-time monitoring systems allows for immediate adjustments to drilling parameters, improving overall performance. By expecting potential soil-related issues, contractors can develop effective strategies that deliver a smoother directional try now boring process and mitigate costly delays.

Pipeline Misalignment Fixes

Poor alignment of pipelines during directional boring can result in substantial complications and delays in project timelines. To tackle this problem, contractors can utilize several corrective measures. First, accurate pre-bore surveys are critical to detect potential alignment difficulties before drilling commences. If misalignment happens, using a reaming operation can help modify the bore path to align with the intended pipeline route. Additionally, employing advanced tracking systems during the boring process allows for real-time adjustments. In cases of severe misalignment, contractors may need to excavate sections of the bore for manual realignment. In conclusion, thorough post-installation inspections guarantee the pipeline meets required specifications, reducing the risk of future misalignment issues. These strategies improve the overall efficiency and success of directional boring projects.

Future Trends in Directional Boring Technology

As demand increases for efficient underground construction methods, the future of directional boring technology is set for significant advancements. Innovations are likely to focus on automation and real-time data analytics, improving precision and efficiency during installations. The introduction of advanced materials will likely enhance the durability and performance of drilling equipment, minimizing maintenance costs and downtime.

Additionally, the integration of machine learning algorithms and artificial intelligence will facilitate enhanced decision-making during complex projects, enhancing drilling paths and minimizing environmental impact. Furthermore, the development of smaller, more compact machinery will allow access to densely populated areas, broadening the applicability of directional boring.

Sustainability is set to play an essential role, with growing emphasis on eco-friendly practices and strategies that lower noise and energy consumption. Overall, these trends reveal a positive shift towards more efficient, effective, and environmentally responsible directional boring approaches in the coming years.

Popular Questions

What Permits Are Needed for Directional Boring Projects?

Directional boring undertakings generally need multiple permits, such as excavation permits, environmental permits, and utility location permits. Regional requirements can differ, requiring consultation with local authorities to ensure adherence to all required legal obligations before commencing.

How Do I Choose the Right Contractor for Directional Boring?

To pick the right contractor for directional boring, one should evaluate their experience, check references, confirm insurance and licensing, evaluate equipment quality, and compare project bids to secure a trustworthy and budget-friendly partnership.

What Environmental Impacts Result from Directional Boring?

This drilling method can lead to soil disturbance, potential groundwater contamination, and negative impacts on local ecosystems. Nonetheless, when handled correctly, it limits surface disruption and can be a more eco-friendly alternative to traditional excavation methods.

What Impact Do Weather Conditions Have on Directional Boring Operations?

Weather conditions substantially affect directional boring operations, as substantial precipitation can result in soil instability, while severe temperature conditions may impact equipment performance. Strong winds and lightning strikes also pose safety hazards, potentially halting or delaying the work.

What's the Average Price of Directional Boring Services?

Average pricing for directional boring services typically ranges from $5 to $15 per foot, contingent upon factors such as job intricacy, soil conditions, and local market rates, influencing overall pricing for contractors as well as clients.